INTRODUCTION OF

THE PHARMACEUTICAL

TECHNOLOGY DEPARTMENT

Job Description

The pharmaceutical technology research professionals conduct technological research related to

discovering the new candidates with high developablity, drug substance manufacturing processes and

formulation, industrialization research that takes into consideration the environment, quality, and

safety, supply investigational products necessary for the start of clinical studies based on development

strategies, prepare materials for approval application through cooperation with quality assurance and

respond to factory inspections, develop mechanisms to supply products in line with sales strategies, and

provide technical guidance for the transfer of manufacturing technologies to overseas hubs, and facility

design. They play a key role in which Astellas speeds up the launch and supply of high-quality new

products. The engineering professionals are responsible for introducing research equipment, building

investigational product manufacturing facilities based on pharmaceutical technology research, and

building manufacturing plants for future commercial production.

Pharmaceutical technology research professionals conduct commercial and CTM production of chemical drug

substances, solid dosage forms, sterile injectables, fermentations, antibodies, and biopharmaceuticals

under strict GMP controls. Pharmaceutical technology research processionals also conduct facility

suitable manufacturing process development, pilot scale process verification, and further process

modifications utilizing the pilot results. By supplying pharmaceuticals globally, we have gained

experience in testing both domestically and internationally, and are building a higher-level quality

system to ensure a stable supply of products to patients.

-

Chemical & Biological Technology Labs. (CBTL)

CBTL is responsible for the “Drug Substance” manufacturing process.

VIEW MORE

The modalities covered by the CBTL are quite diverse, from chemically synthesized products to fermentation products, biologics, virus drugs, and cell therapy products derived from stem cells. In addition, we have introduced cutting-edge robotics and digital technologies, and are diligently proceeding with research into continuous manufacturing technology for antibody and the mechanization and automation of DS manufacturing processes and operations for cell therapy products. -

Analytical Research Laboratories

In order to deliver drugs with high functionality and appropriate quality to patients, the Analytical Research Laboratories supports Astellas’ development of manufacturing technologies from the quality aspect through high-level product understanding and analytical development based on physicochemical, biochemical, and analytical chemistry from the late stages of pharmaceutical product development after the acquisition of proof-of-concept (POC) to post-marketing.

VIEW MORE -

Pharmaceutical Research and Technology Labs

The mission of the Pharmaceutical Research and Technology Labs is to deliver highly functional, high-quality new drug products to patients and medical settings around the world in a timely manner.

VIEW MORE -

CMC Research

Pharmaceutical Science & Technology Labs (PSTL) is in charge of a broad range of pharmaceutical technology research operations for all early-stage development projects in all modalities, such as small molecules, antibodies, proteins, nucleic acids, viruses, cells, and the new challenge of Rx+ products, etc. We strive to obtain “the fastest proof-of-concept (POC)” for development-stage products by leveraging our strong manufacturing/analytical technological capabilities.

VIEW MORE -

Engineering Group

The Engineering Group works on "engineering" and "technology development" activities. In both of these tasks, we work to optimize the entire procedure based on environmental, safety, quality, delivery time, and cost perspectives. But technology development focuses on installation of new technology, digital technology and automation technology.

VIEW MORE -

Takahagi Technology Center

Takahagi technology center are always challenging to synthesize wide variety of chemicals toward drug substance supply for the commercial and clinical purposes as a leading drug substance manufacturing site in Astellas.

Introduction Working employees Working place -

Yaizu Technology Center

As the lead plant for drug products and biopharmaceuticals, we are strengthening our coordination with the Formulation Research Center to enhance our commercialization technologies and expedite stable production.

Introduction Working employees Working place -

Toyama Technology Center

Toyama Technology Center is the base for the biological commercial products of Astellas. In addition to the manufacturing of commercial products, we also improve the manufacturing processes, scale-up the process in the late development stage, and manufacture the active pharmaceutical ingredients for the clinical study use. Through these activities, we also play an important role in development of engineers who will be responsible for stable product supply into the future.

Introduction Working employees Working place -

Takaoka Plant

The Takaoka Plant specializes in manufacturing of injection products.

Introduction Working employees Working place

We have several capability to manufacture injection products and continue to evolve in line with the times as a base for the development of injection products.

Chemical & Biological Technology Labs. (CBTL)

CBTL is responsible for the “Drug Substance” manufacturing process.

The modalities covered by the CBTL are quite diverse, from chemically synthesized products to

fermentation products, biologics, virus drugs, and cell therapy products derived from stem cells. In

addition, we have introduced cutting-edge robotics and digital technologies, and are diligently

proceeding with research into continuous manufacturing technology for antibody and the mechanization and

automation of DS manufacturing processes and operations for cell therapy products.

Process Chemistry

We have achieved a "stable supply of drug substances" using chemical synthesis

technology. Our main activities are as follows; (1) developing manufacturing methods for synthetic

drug substances, (2) transferring technology to production sites, manufacturing and supplying large

amounts of drug substances, (3) life cycle management of pharmaceuticals (manufacturing troubles,

stockout avoidance, cost reduction, etc.). In order to ensure a stable supply of drug substances, we

are developing cost effective manufacturing method to deliver high quality drug substances,

considering safety and the environment. Therefore, we are a group of specialists with not only organic

synthetic technology but also multiple technology and knowledge such as separation and purification,

analysis, production, chemical engineering, safety environment, GMP, and regulatory requirements. In

addition, we are also devoted to acquiring new technologies such as flow synthesis, fine bubbles, and

experimental research automation, etc.

We have the only EHS research function in Astellas. As for safety measures, we evaluate all synthetic

processes before manufacturing, and as for environmental measures, we evaluate activated sludge

process at inside and outside production sites.

We also provide technical supports at overseas production sites and apply for new drug approvals to

overseas authorities such as the FDA and EMA. Therefore, there are opportunities for researchers to

play an active role globally, not just in examining experiments within the laboratory.

Bioprocesses Science

Bioprocess Science is responsible for process development for manufacturing

biological drug substances.

mAb an example, the bioprocess can be divided into cell line development,

cell culture process development and purification process development.

Cell line development

The construction of antibody-producing cell line is like a treasure hunt. It is a

task to create and find robust CHO cell line that have high antibody productivity, appropriate product

quality, and can withstand large-scale cell culture in future commercial production. We have been

building a platform how to integrate antibody genes into CHO cells and how to find better candidates

efficiently by accumulating experience.

There is the pressure of tight deadlines, however, we sincerely collect and analyze data for thousands

of candidate cells and select right one that will support subsequent production. We believe this bring

VALUE to patient.

Cell culture process development (Uptream Bioporcess Science)

We are mainly in charge of the cell culture process development for producing

macromolecules such as antibodies using CHO and microorganisms. We cover a wide range of product

lifecycle, from supplying research sample at the initial development stage to establishment the

process for stable production, technology transfer to manufacturing sites, biologics license

application, and supporting the manufacturing of commercial products.

The role of cell culture process development is to establish a stable culture process even on a large

scale. In order to stably deliver drugs to patients, it is essential that the manufacturing process is

highly reproducible and operates stably. We are deepening our understanding of the effects of process

parameters such as temperature, pH, etc. on cell culture performance and product quality, and we are

establishing robust culture processes with scientific knowledge. In addition, we improve productivity

by optimizing culture medium and culture conditions, improve quality, reduce costs, and troubleshoot

when problems occur in manufacturing.

Purification process development (Downstream Bioprocess Science)

We are responsible for purification process development for biologics. There are many impurities and target substance-derived impurities/related substances in the cell culture solution. In order to efficiently isolate and purify high-quality target substances from culture fluids, we establish a low-cost and environmentally friendly purification process by combining the cutting-edge technologies such as solid-liquid separation, column chromatography, and membrane concentration. For industrialization, we are also working on process automation research to improve the efficiency of manufacturing processes.

Process Engineering

There is a process engineering laboratory that fulfills gaps between process development and commercial production with bio-& chemo-engineering, mechanization/automation, and Dx technology such as simulation.

Main research themes

[Process Chemistry]

Process development of synthesis routes for new drug substances with pharmacological activity and

technical support during manufacturing

Manufacturing process development assuming commercial production and technology transfer to

manufacturing site

Environmental and health safety research related to the entire drug substance manufacturing process

Approval applications worldwide including Japan, Europe, and America, and technology transfer to

manufacturing sites

Cutting edge technology development

[Bioprocesses Science]

Process development for manufacturing biological drug substances aiming at world-class standards

Technology transfer of manufacturing process for biological drug substances to manufacturing sites

Biologics license application and supporting the manufacturing of commercial products

Cutting edge technology development

A Message from the head of Chemical & Biological Technology Labs.

Hideto Yamaguchi

In April 2020, the Chemical & Biological Technology Labs. was established by merging the Synthetic

Processes Research Laboratory, responsible for the development of synthetic processes for small

molecule drugs, and the Bioprocesses Research Laboratory, responsible for the development of culture

and purification processes for biopharmaceuticals such as antibody products, in order to fully realize

the utilization of CMC research and development for various modalities.

The modalities covered by

the Chemical & Biological Technology Labs. range from chemically synthesized compounds to fermentation

products, biopharmaceutical products, and even virus-based products and cell-based products produced

by inducing differentiation of stem cells. If it can become a pharmaceutical product, the Chemical &

Biological Technology Labs. is in charge of the entire development of the drug substance manufacturing

process. In addition, for modalities with immature drug substance manufacturing technologies such as

viruses and cells, we introduce state-of-the-art robotic and digitalization technologies, and we are

advancing research on the mechanization and automation of drug substance manufacturing facilities and

operations.

It takes 10 years to get a drug on the market. During this period, the manufacturing process

development begins with the acceptance of the manufacturing method in the early stage of research, and

it requires a deep scientific understanding of the target product and manufacturing process,

development of a robust process that can withstand commercial use, acquisition of regulatory approvals

in each country, and technology transfer to domestic and overseas manufacturing plants. Even in the

same process development, there are different challenges in each development phase, and researchers

affiliated with the Chemical & Biological Technology Labs. have the opportunity to accumulate a lot of

experience in pharmaceutical product manufacturing.

Global development is one of the characteristics of Astellas’drug substance process development

research. Under Astellas’ vision of "On the forefront of healthcare change to turn innovative science

into VALUE for patients," we continues to add companies and researchers who are at the cutting edge of

science overseas to our organization. By combining our previous experience in manufacturing with

advanced science, we are taking on challenges every day to bring first-in-class and unique

pharmaceutical products to patients as quickly as possible.

Astellas is looking for passionate

researchers who can work globally while valuing teamwork, and who can personally create their own

future and innovative research areas.

Employee Q&A

I study the method for the scale-up synthesis of drug substances, which is active pharmaceutical ingredients.

Master of Molecular Pharmaceutical Science, Graduate School of Pharmaceutical

Sciences

Joined the company in 2022

Honoka Teraji

-

What is your current job description?

I study the method for the scale-up synthesis of drug substances, which is active pharmaceutical ingredients.

In order to deliver pharmaceuticals to patients around the world, we must be able to scale-up synthesis of drug substances. Since the quality of pharmaceuticals directly affects the health of patients, a manufacturing method that can stably supply high-quality drug substances is necessary. In scale-up synthesis, it is also necessary to consider the environment and safety, and to aim for cost reduction.

At the Chemical & Biological Technology Labs, we are developing manufacturing methods that enable the stable, safe, and low-cost supply of high-quality drug substances. We are responsible for work related to drug substances in a wide range of development phases, from lab-scale experiments to large scale manufacturing for commercial products and post-marketing life cycle management. In addition, we are able to be involved in operations necessary for the stable supply of drug substances, such as submitting applications to the regulatory authorities and managing starting material sources and manufacturing sites.

I am in charge of small molecule drugs in the early stages of development, and developing manufacturing methods for the first chemical synthesis of drug candidate compounds on a kg scale. The drug substances produced will be used for formulation studies and clinical trials, so it is necessary to establish a manufacturing method that enables synthesis with a predetermined quality and schedule. Within a limited time frame, I search for appropriate routes and reaction conditions by repeating the cycle of hypothesizing, experimenting, and discussing. I also discuss with my colleague to get hints and obtain information through literature research, challenging myself to improve the manufacturing method to a high quality. When I was in university, I often thought only about the "target compound," hoping to synthesize it, but since joining the company, I have been able to think more deeply about "how to synthesize" compounds.

I feel each job is worthwhile when I think that there are patients waiting for the drugs we synthesize. -

When do you find work interesting or difficult?

Synthesizing large quantities of drug substances is difficult, but also interesting and fulfilling work.

I find the process of achieving scale-up synthesis both interesting and difficult. When deciding on a synthesis method in the laboratory, we consider many things. For example, the reaction conditions for high yield, whether the reaction proceeds in the same way each time, how to synthesize from even the cheapest starting materials, how to remove or reduce impurities, how to reduce the workload at the manufacturing site, and so on. There are many items to be considered, and I feel that it is difficult to choose a policy and selection for consideration. That said, I find research interesting when I can prove a hypothesis or find the cause of a problem.

If I were to do chemical synthesis on my own, I would be limited to a few 10g scale at most. I was surprised to see how many people are involved in the safe and high-quality synthesis on the scale of several 10kg to several 100kg. For example, we work with an environmental safety team that confirms that the manufacturing process we have created is safe for operations, a quality assurance department that confirms that the quality of the drug substances can be assurance using the established manufacturing process and test methods, and the manufacturing site where is actually produced according to the manufacturing process. I feel a great sense of accomplishment when I succeed in synthesizing a large amount of drug substances as a result of our close collaboration with the relevant departments. -

In your work, what challenges would you like to take on in the future?

I would like to take on the challenge of working in a wide range of phases, from the early stages to commercial stage.

I would like to become a process chemist with a broad perspective and would like to experience all the processes involved in the supply of drug substances. From synthesizing a small amount of a drug candidate compound to putting it on the market and managing its stable supply, I need to understand not only organic chemistry but also chemical engineering, safety engineering, application-related laws and regulations, and many other fields. Furthermore, in order to work smoothly as a team throughout the company, it is necessary to understand and consider the processes before and after my own department. Since many of the starting material manufacturers and manufacturing plants are overseas, communication in English is also important. In my second year with the company, I am still learning, but I would like to continue to take on challenges in my daily work. I believe that the environment in which I can take on the challenges of projects in various phases is only possible at the Chemical & Biological Technology Labs, which handles everything from initial development products to commercial products in one place.

-

What is the appeal of working at Astellas?

I am attracted to a work environment where I can take on a variety of challenges and work easily.

We feel that this is an attractive environment in which to work. First of all, there is an environment where you can concentrate on your experiments. We have a wide variety of equipment, reagents, and analytical instruments for the experiments we want to conduct. We can work in teams of several people to challenge new trial, and we receive support in various ways, such as the introduction of necessary equipment. In addition, there is a culture of easy communication with people in the workplace. Regardless of the year, we are able to help each other by sharing our opinions and suggestions and receiving advice on experiments. New ideas are often born out of chit-chat. It is a good work environment in terms of work-life balance. FF Day, in which finish work earlier on Fridays, has been introduced, and paid vacations are easy to take, so employees can refresh themselves regularly. Many employees work according to their life events, such as male employees taking maternity leave.

Another major attraction of this company is that employee growth is generously supported. Rotational training, in which employees visit related departments, allows them to deepen their understanding of their work and how their own department's work is related to the processes before and after them. When I participated in training for a department that handles biopharmaceuticals in the same laboratory, it was an opportunity to deepen my understanding of biopharmaceuticals and reconsider the characteristics of small molecule pharmaceuticals. In particular, we have a significant relationship with the manufacturing plant, which synthesizes drug substrates using the manufacturing process we created, allowing us to experience the manufacturing site over a six-month period. The scale-up from the laboratory to the manufacturing site is not simply a difference in size. The perspectives that can be learned from the manufacturing site are also important for future process development, and I find it attractive to be able to experience this as training. In addition, we have other systems in place to support self-improvement, such as participation in domestic and international academic conferences and support for degree acquisition. The fact that there are many people challenging themselves to achieve their goals is a good stimulus, and I think it is an environment where we can grow together.

A day in the life of Honoka Teraji

| 8:30 | Arrive at office, check email and daily schedule |

| 8:30 to 12:00 | Experiment : Prepare and track reactions, collect experiments from the previous day |

| 12:00 to 13:00 | Lunch at the company cafeteria. You can have a delicious lunch with many varieties at a reasonable price. |

| 13:00 to 15:00 | Sometimes there are meetings with the team or research contractors. |

| 15:00 to 15:30 | Take a break for discussion at the company café. There is a daily menu, which is fun. |

| 15:30 to 18:00 | Summary and discussion of experiments and confirmation of tomorrow's schedule. |

| 18:00 | Leave the office. Sometimes we go out to dinner with our peers. |

Employee Q&A

Development of the cell culture process for antibody pharmaceuticals.

Completed Ph.D. in Computational Biology and Medical Sciences

Joined the

Company in 2021.

Masaru Shimojo

-

What is your current job description?

Development of the Cell Culture Process for Antibody Pharmaceuticals.

I am working on the development of cell culture processes for the production of antibody pharmaceuticals. Pharmaceutical companies have a responsibility to consistently deliver high-quality and safe products to the many patients in need. To achieve this, it is necessary to develop a process that not only verifies the effectiveness and safety in clinical trials but also produces and supplies high-quality products. In the case of antibody pharmaceuticals, it is necessary to develop a cell culture process that maximizes the productivity of the cell line producing the antibodies and demonstrates stable quality.

Furthermore, the developed process must not only be demonstrable at the laboratory scale but also ensure equivalent performance when scaled up to bioreactors hundreds to thousands of times larger than the laboratory scale. Therefore, we are concurrently working on various technological developments in parallel with our process development tasks, utilizing them to enhance the development of better processes and their scale-up evaluations.

In addition, process development work is sometimes carried out in collaboration with other companies. We discuss the planning of experiments and interpretation of results needed for process development while progressing together. As we often collaborate with overseas companies, there are opportunities to engage in global work, which requires proficiency in English for effective communication. -

When do you find work interesting or difficult?

The Fascination of Encountering "New Things" and the Challenge of Solving Them

What I find interesting about this job is that I encounter a lot of "new things." In the field of biopharmaceuticals, there are many "new things" such as the process development for new antibody molecules or New Modalities, advancements in technology, the introduction of new equipment, and the absorption of new knowledge. However, for every encounter with something "new things," an equal number of "challenges" arise. "Challenges" like developing the suitable processes for new molecules/New Modalities and establishing the operational systems to ensure that newly introduced equipment is accessible to everyone, and more, also emerge in abundance, and more, also emerge in abundance. It can be difficult to solve these "challenges" on my own, but through discussions and verifications with the team, we can lead to new discoveries and find solutions, which in turn adds to the excitement. I consider myself fortunate to be able to work at Astellas, where such an environment exists, as I have a curious and inquisitive nature.

-

In your work, what challenges would you like to take on in the future?

Reliable and Swift Process Development and Challenging Technological Advancements

In pharmaceutical process development, I understand that ensuring reliability in the work is crucial, as it is necessary to develop a process for producing active pharmaceutical ingredients stably without causing delays to the schedule. In recent years, Astellas has seen an increase in achievements in process development for antibody pharmaceuticals, and a platform for process development is beginning to take shape. However, many specialized antibodies like bispecific antibodies come into play on the development stage. It becomes necessary to optimize the process for each molecule. Therefore, I aim to leverage scientific knowledge and experience for any type of molecule, in order to swiftly develop a reliable process.

Additionally, new technologies in the field of biopharmaceuticals are advancing at an astounding pace. To avoid falling behind in the industry, it's crucial to constantly monitor new technologies, evaluate their potential usefulness for our company early on, and take in those valuable technologies. While implementing such technologies may take time, I consider it a highly rewarding endeavor, as it could potentially elevate our company's technological capabilities. I'm eager to take on these challenges actively. -

What is the appeal of working at Astellas?

Open and Transparent Work Culture

Even as a young professional, I feel comfortable expressing my opinions in this open and communicative work environment. As a result, each individual is able to showcase their unique personalities and expertise while collaborating effectively on tasks. In meetings, there is active exchange of ideas, regardless of whether someone is a young professional or a seasoned veteran.

Furthermore, I perceive that young professionals are provided with numerous opportunities for growth, such as participation in conferences. While the shift to online participation has increased due to the impact of COVID-19, there are still opportunities to attend international conferences locally, allowing us to stay updated with the cutting-edge developments in the industry. If there is an interest in new technologies from other companies, regardless of one's seniority, arranging meetings or attending seminars is possible, facilitating information gathering.

Moreover, the company as a whole is dedicated to promoting work-life balance, including both work and parenting. In my department, it is relatively easy to take maternity or paternity leave, and many individuals, regardless of gender, have taken advantage of this opportunity. I myself took paternity leave when my first child was born.

A day in the life of Masaru Shimojo

| 6:00 | Wake up. Get ready with the family. |

| 7:30 to 8:30 | Commute to work. Review the day's schedule. |

| 8:30 to 9:15 | Daily team meeting. Review progress and coordinate tasks. |

| 9:15 to 12:00 | Conduct experiments. Collaborate with the team. |

| 12:00 to 13:00 | Lunch in the company cafeteria. Take a break to prepare for the afternoon. |

| 13:00 to 16:00 | Meetings. Share experiment results and engage in discussions as needed. |

| 16:00 to 17:45 | Desk work. Plan experiments, prepare reports, conduct literature research, etc. |

| 17:45 | Leave work. Pick up my daughter from daycare, and return home. |

Pharmaceutical Research and Technology Labs

Overview

The mission of the Pharmaceutical Research and Technology Labs is to deliver highly functional,

high-quality new drug products to patients and medical settings around the world in a timely manner. Up

until now, we have created outstanding pharmaceutical technologies, such as solubilization of poorly

water-soluble drugs, controlled-release of drugs, and drug delivery systems (DDS) to create additional

value in products, all of which can provide value to patients. We contribute to projects at a wide range

of stages, from the creation of new themes with Research teams, through pre-clinical and clinical

development stages, applications for new drug approval, and technology transfer to commercial

manufacturing sites, as well as the stable supply of drug products. In other words, contributions of

pharmaceutical research starts at the very early research stage to evaluate the physicochemical and

biopharmaceutical properties of drugs, proposal and investigation of DDS concepts, and continues until

commercialization, including formulation development, process development, scaling up for

industrialization, and packaging and device development. For example, we are constantly collaborating

with production facilities in Japan and overseas (US, Europe, etc.) through various activities such as

technology transfer of new products, process improvement, cost reduction of existing products, and

strive to establish manufacturing know-how that is excellent in cost performance and environmentally

friendly.

In addition to conventional small molecule compounds and antibody drugs, we have recently been working

on formulation research targeting new therapeutic modalities such as nucleic acid drugs, and cell

medicines, and are promoting formulation development research globally in collaboration with overseas

development bases (Chicago and Boston in the US, the Netherlands in EU, etc.) as well as domestic sites

(Yaizu and Tsukuba).

Furthermore, we have developed novel drug products with enhanced functionality for key products,

contributing to the maximization of value for these products. If pharmaceutical products are used in

combination with superior pharmaceutical technology including DDS, the value of these products will

continue to grow. Recently, we have been actively working on apps development, formulation design AI and

Dx. We will continue to advance Astellas' pharmaceutical technology as much as possible, nurture

products supported by our technical capabilities, and provide them to the world.

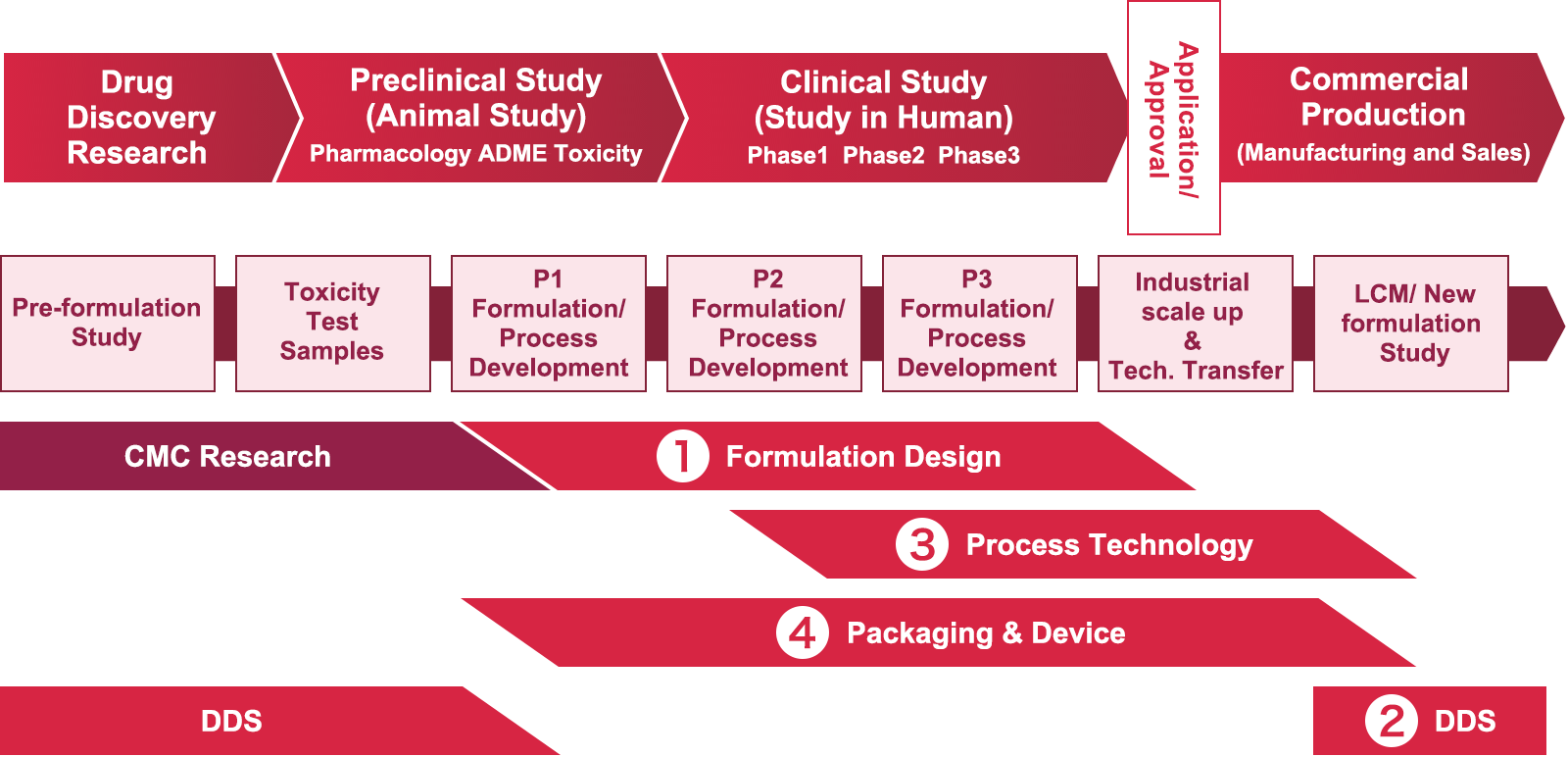

Relation between drug development and Pharmaceutical Research and Technology Laboratories

In order to demonstrate the efficacy and safety required for drug products, any one unit (= 1 tablet, 1 capsule, 1 vial) has the same quality, and excipients are necessary to make it easy for patients to use. The main task of the formulation design is to determine the optimal combination and optimal amounts of excipients to be added to the formulation (= determination of formulation), and to design the formulation to the optimal dosage form. It is a heavy responsibility, but it is a very rewarding job, because formulation has a big impact on whether a drug product is easy to manufacture, easy to use, and highly safe and effective.

Since the role required for the formulation differs depending on the clinical phase, we will refine the formulation by identifying the characteristics of the active ingredients while developing formulation that satisfies the goals of each phase. Usually, the final formulation (= the formulation to be marketed in the future) is decided by the late-stage clinical trial and supplied as clinical trial materials. In recent years, development of formulation design AI is being pursued in order to achieve fast and efficient formulation development.

On top of that, while proceeding with the formulation design activities, we will investigate the manufacturing method and manufacturing conditions, as well as the packaging. Therefore, the information obtained from these investigations will be the basic information for commercialization (mass production) activities after the late-stage clinical phase at the Process Technology and packaging design activities.

Drug Delivery System (DDS) is the formulation technology to control distribution of drug substances in the body after dosing. To improve efficacy, adverse effects and user-friendliness, DDS lab. is researching technologies to deliver drug substances (small molecules, antibodies, proteins, nucleic acids, cells, phages etc) to target sites more efficiently and certainly.

For the purpose of "delivering DDS products of values to patients", we investigate, propose, prepare and evaluate (in vitro/vivo) many kinds of formulations such as nanoparticles, gels, local formulations, injectables, oral dosage forms for various target sites and diseases of the below (1) and (2). (1) For needs of drug discovery, we study DDS technologies with researchers of several fields, find the optimal formulations for clinical studies, and apply patents. (2) For drug substances after launch or in late clinical stages, we study new formulation idea to enhance values with members of development and sales.

Our labs are in Tsukuba Ibaraki and Yaizu Shizuoka. We’re collaborating with formulation design researchers and CMC-Research for CTM supply, and package and device researchers for device application. We're also developing new DDS technologies for cell therapy with AIRM in US.

The main task of the Process Technology is developing a manufacturing process for commercial production with high quality, high efficiency and low cost by using final Drug product formulation developed by the Formulation Design.

Participating mainly from late clinical phase, we will lead a technology transfer to global manufacturing sites collaborating with many related departments inside and outside the company. Especially, the new aseptic drug product manufacturing lines are newly established in Yaizu for the increasing importance of aseptic products. We contribute enhancing our aseptic manufacturing capability through the process development.

In new modalities such as cell therapy products, which have made remarkable progress in recent years, we initiate an investigation from early stage because it is extremely difficult to establish manufacturing reproducibility due to their quality characteristics.

The development of new technology is also an important mission, and we are contributing to stable production of new products through the development of cutting-edge data mining systems for the objective of utilizing big data in pharmaceutical plants and research on Process Analytical Technology.

With the motto "Research that is close to patients around the world", we are working on the design and development of packaging and devices that correspond to the diversifying modalities of pharmaceuticals.

We design packaging based on the selection of appropriate materials and maintain the quality of the product over time. We contribute to the reduction of the environmental impacts of our products through the development of environmentally friendly packaging technology, such as the world's first successful use of biomass-derived plastic in blister packages as the primary packaging for pharmaceutical products. Since packaging and devices are touchpoints with patients and healthcare professionals, it is important to ensure not only medical safety through measures such as prevention of medical malpractice and countermeasures against counterfeit drugs but also medication adherence and quality of life through the application of universal design.

In recent years, we have also developed combination products that combine pharmaceuticals and medical devices, digital apps (Software as Medical Device) development for DTx (Digital Therapeutics) , and new technologies such as packaging automation with collaborative robots.

Main research themes

Formulation development/process development, industrialization, and package development for new drug

products

Formulation development/process development, industrialization, and packaging development to maximize

the value of existing products

Study on Drug Delivery Systems (DDS) to improve efficacy and safety

Development of new dosage forms with high functionality or convenience, new formulation technologies,

combination products with pharmaceutical products and medical devices (devices), and new packaging

forms

Formulation development of various therapeutic modalities such as small molecules, antibodies, nucleic

acids, and cells.

Improvement of oral absorption of poorly soluble drugs

Research on process analytical technology to understand and control the critical quality attributes that

affect product quality

Implementation of big-data analyses on commercial production sites for higher product understanding and

proactive process improvement

Scale-up research for various formulations and manufacturing methods

New industrialization research on various formulations and manufacturing methods (process and equipment

development) Study on optimization of manufacturing conditions for process improvement and quality

improvement

A Message from the head of Pharmaceutical Research and Technology Labs

Hiroyuki Kojima

New compounds with pharmacological activity will finally become pharmaceutical products (medicines)

that can be administered to patients through pharmaceutical research. There are a variety of

formulations, including oral formulations such as tablets and capsules, injectables, transdermal, and

inhalation, etc. In addition, there are a lot of technologies that can be incorporated into each

formulation to optimize/maximize treatment effects. For this reason, researchers with knowledge and

technical skills not only in pharmacy but also in physical chemistry, biology, and mechanical

engineering have been working at Pharmaceutical Research and Technology Labs. The products developed

by our researchers via formulation development, process design, and packaging and device development

are clinically used to treat patients worldwide. In addition to small molecules and antibodies, we

have recently been focusing on pharmaceutical research of cell-based and mRNA LNP products, as well as

development of apps, formulation design AI, Dx, drug delivery systems and new pharmaceutical

technologies to maximize the value of drug product.

As one of the research areas closest to patients, clinical, and pharmaceutical products, we are

honored and proud of our pharmaceutical research that generates products in all modalities. In order

to deliver higher-value pharmaceutical products to patients around the world as soon as possible, why

not work with us at the "Pharmaceutical Research and Technology Labs" where we work hard on research

every day in cooperation with not only domestic but also overseas bases such as Chicago/Boston in the

US and Netherland?

Employee Q&A

We research to find the optimal drug delivery system (DDS) for "drug seeds" having pharmacological effects for enhancing the delivering value for patients.

Master of Pharmacy、School of Pharmaceutical Sciences (6-year program)

Joined

the company in 2020

Ayaka Masuda

-

What is your current job description?

We research to find the optimal drug delivery system (DDS) for "drug seeds" having pharmacological effects for enhancing the delivering value for patients.

“Drug seeds” (active ingredients or drug substances) include various modalities such as small molecules, antibodies, nucleic acids, and cells etc. Pharmaceutical research is converting them into “drug products” that can be administered to patients. In the research area, DDS is a technology to control movement of the drug substances in the body after administration. To improve drug efficacy, reduce side effects, and/or improve patients convenience, our challenge is to create drug products for delivery of the optimal amount of drug substances for the appropriate time to the best sites in the body where the drugs perform their efficacy.

I’m working at DDS Laboratory. We investigate and select the optimal DDS technologies for each modality and issues, when it’s difficult to develop the "drug seeds" to drug products due to their insufficient efficacy and/or extensive side effects etc. If there is no suitable technology, we investigate and create a new pharmaceutical technologies, i.e., a novel invention. We hear voices and needs of patients and medical professionals from other departments members in such as sales reps, and we confirm what kind of formulation is required.

We prepare and evaluate prototype DDS formulations in vitro and in vivo to confirm their performance. These evaluations are conducted by ourselves, and sometimes by research division members with specific techniques. After execution of cycles of the studies to improve formulations performance, we file formulation patents application if the concept of DDS technology is confirmed.

To realize the prototype DDS formulation into “drug products” having higher quality, stable manufacturing, we relay the baton to researchers of Formulation Design Laboratory and CMC Research. They investigate optimization of formulation compositions, such as types and amounts of excipients, and manufacture investigational drugs for clinical trials. To establish stable and efficient manufacturing process for the high-quality “drug products” with low cost, researchers at Process Technology Laboratory optimize the process, and transfer the technology to global manufacturing sites. To protects the quality of “drug products” during long-term storage and transportation, researchers at Packaging and Devices Laboratory design the optimal packaging which is easy to use for patients and medical professionals. In recent years, we also develop administration devices for easy dosing and medical apps (Software as Medical Device).

In addition to experiments and collaboration with various experts, search and understanding of the world's cutting-edge DDS technologies are also important aspects for us. Reading the latest and cutting-edge papers and patents enables us to select the most suitable DDS technology for each modality and issue and promote development of drug products. -

When do you find work interesting or difficult?

Research often does not progress as expected, but I feel pleasure of being able to quickly deliver high value to patients, and scientific interesting when we obtain experimental data which contribute to projects promotion even a little through trial and error with team members.

In some projects, we discuss with overseas members in English. Previously, when I proposed a future plan based on our data, miscommunication prevented smooth discussion and obtaining consensus. Therefore, I obtained additional data, improved phrasing and expression, and finally, I could get consensus on our idea and felt a sense of accomplishment. -

In your work, what challenges would you like to take on in the future?

I would like to try formulation development for various “drug seeds” and deliver the value to patients.

Issues to be solved and the suitable formulations depend on the modality of “drug seeds''. Content of investigation and collaboration partners also differ between drug discovery projects in early stage and development of additional dosage forms for launched products as LCM (life cycle management). In order to make drug products of the various “drug seeds” launched, I intend to continue to challenge technology search and formulation preparation, accumulate knowledge and experience, and would like to contribute to “value for patients'' as a formulation researcher.

Moreover, expertise in many fields is essential to promote projects. For commercialization of products, it’s extremely important to communicate with a variety of key stakeholders having expertise such as pharmacology, synthesis, pharmacokinetics, safety, regulation, stability, equipment etc.. Mutual understanding is also a key for success in collaboration with academia and startups.

I would like to learn more knowledge from my seniors, expand my views as a pharmaceutical scientist, and continue to take on challenges together with colleague teams. -

What is the appeal of working at Astellas?

We can feel our own growth while receiving cooperation and support from many colleague.

As one of attractive points in working with Astellas, we, young researchers, can be assigned to a responsible researcher of a project, receive generous support from our senior colleagues, and grow ourselves through the projects. In organizational culture of Astellas, employees share own thoughts and ideas and respect each other, regardless of age or department.

In my second year working in Astellas, I was assigned as a responsible researcher of a project for the first time, and I didn't know what/how to proceed with the project and how to collaborate with colleague etc. At that time, I received many advice and suggestions from my seniors and team members, and tried candidate ways by myself, and gradually I was able to proceed the project more smoothly. Even now, I sometimes consult with my seniors when I don’t have confidence in selection of options. Senior colleague always take time to listen to my opinions and give me thoughtful advice even in their busy time. I believe, another attractive point in working with Astellas is that we can respect many seniors not only as a researcher, but also as a person.

Additionally, Astellas has many programs for employee’s growth. For example, young colleague, called mentors, teach the basic social manners and company rules to new commers (one and a half years after joining Astellas). To encourage growth as scientists, there are several supporting systems such as obtaining Ph.D. degrees, participation in academic conferences, and visiting scholars at foreign academia.

I will continue to grow myself day by day so that I can become a reliable senior for my juniors.

An example of my daily schedule

| 8:30 to 9:00 | Come to the office. Check e-mails and confirm my schedule for the day. |

| 9:00 to 10:00 | Discuss experimental data with team members to determine our future plan. Sometimes the discussions are in English. |

| 10:00 to 12:00 | Do experiments. Check e-mails during breaks. |

| 12:00 to 13:00 | Lunch with department members at the cafeteria in the research center. Relax and enjoy playing table tennis with everyone. |

| 13:00 to 14:30 | Do experiments. Check e-mails during breaks. |

| 14:30 to 16:30 | Read scientific papers. |

| 16:30 to 17:30 | Summarize experimental data and prepare presentation materials for meetings. |

| 17:30 to 18:00 | Check e-mails and schedule for the next day, and then I go back home. (Time to go home is different depending on the day, and sometimes I go home earlier. Since business hours is 8:30-15:45 on every Friday, I enjoy playing tennis with my colleagues at the company tennis court around 16:00.) |

* Affiliation at the time of posting.

Analytical Research Laboratories

Overview

The Analytical Research Labs. supports Astellas' "MONOZUKURI" technology development in terms of quality

through high-level physico-chmical/biological and analytical research based on physical chemistry,

structural chemistry, biology, and analytical chemistry from the early stages of drug development to

post-marketing stages, in order to deliver highly functional and appropriate quality drugs to patients.

Specifically, we develop test methods, set quality standards, and conduct stability evaluations based on

research into the physicochemical, structural chemical, and biological properties of active

pharmaceutical ingredients (APIs) and their formulation characteristics. In addition, we transfer the

technology of test methods developed by the Analytical Research Laboratories to the testing departments

at domestic and overseas testing sites and manufacturing sites, and provide analytical technical support

by offering more optimal test methods throughout the product life cycle.

The network of the Astellas Analytics is expanding, centered on the Analytical Research Laboratories,

Astellas US Technologies Inc. in the US, and Astellas Pharma Europe B.V. in Europe, with researchers

working on a global basis.

Furthermore, they prepare analytical and quality-related technical documents for clinical trial

applications and new drug applications in various countries around the world, and work with regulatory

affairs departments in Japan and overseas to handle the approval review process, as well as responding

to applications for changes after approval. As the number of countries subject to regulatory approval

expands and pharmaceutical regulations strengthen globally, we aim for early approval by conducting

highly reliable, scientifically based physical property and analytical research. In particular, we are

introducing new analytical research concepts such as Analytical Quality by Design (AQbD), a new

analytical technology based on Chemometrics, and utilizing data science, as well as developing cell

based assays and functional assays for biopharmaceuticals. For biopharmaceuticals, we are actively

engaged in the development of cell-based assays, functional assays, and characterization methods using

high-resolution LC-MS.

Main research themes

Development of new analytical methods, application of new technologies to pharmaceutical analysis, and

solution of problems in APIs/formulations through scientific approaches

Analytical research on APIs; physical property research, test method development and specification

setting, stability evaluation, etc. to support process development of APIs

Analytical research of pharmaceutical formulations; physical property research, test method development

and specification setting, stability evaluation, etc. to support formulation research, process

development and packaging design development

Technology transfer of test methods and maintenance of analytical technology to the testing departments

of group companies, contract testing companies outside the group, and manufacturing site testing

departments inside and outside the group.

Preparation of submission materials for Japan, the U.S., Europe, and other emerging countries, and

handling of approval reviews and change applications

Development of cell based assays and functional assays for biopharmaceuticals, characterization and

method development using high resolution LC-MS, and genome analysis using NGS, etc.

Introduction and development of new analytical techniques based on chemometrics, new analytical research

concepts such as AQbD, and data science-based methods for investigating the causes of quality issues in

CMC research.

Robotics for CMC research and study of automation of quality testing at test sites.

Message from Vice President

Kei Motonaga

The function and quality of a pharmaceutical product are not simply expressed by the analytical

results of the final product, but are created through a research process that determines relevant

properties throughout the research and development of the drug substance and drug product, and leads

to more sophisticated process establishment, formulation design, and packaging design. The name

"Analytical Research Labs." is derived from the concept of "scientifically exploring the critical

properties of products".

The scope of our work ranges from the initial development stage to the end of the product's lifecycle.

The countries where applications are filed and the production sites are increasingly globalized.

Research and development (R&D) targets are not limited to active ingredients such as viruses, cells,

antibodies, and chemically synthesized pharmaceuticals, or to their formulations themselves, but also

include pharmaceutical excipients such as functional polymers, which require various characterization

technologies as formulation and device functionnalites become more and more sophisticated. The

Analytical Research Labs. is open to all researchers, regardless of their field of expertise, who wish

to find their own dream in bringing valuable medicines to the patients in the world.

Employee Q&A

I develop analytical methods to evaluate the quality of drug products of small molecule and conduct research to understand their physico-chemical properties.

Joined in 2021, graduate of master's degree at the Graduate School of Medical and Pharmaceutical Sciences (Pharmaceutical Sciences)

Hitomi Okada

-

What is your current job?

In order to deliver highly functional, high-quality drugs to patients as quickly and stably as possible, I am engaged in the development of test methods and research on the physico-chemical properties of drug products.

Proper design and manufacturing of drugs and assurance of their quality are essential to deliver safe and reliable drugs to patients. In the Analytical Research Labs., we mainly develop test methods to evaluate the quality of drugs (drug substances and drug products) and conduct research to understand their physico-chemical properties.

I am currently in charge of the development of test methods and research on the physico-chemical properties of small molecule drug products (formulated products for administration to patients) under development.

In the test method development, we control the quality of drug products by setting test procedures and acceptance criteria from the development stage when clinical trials are initiated. As the development progresses, the level of control is increased to achieve higher quality in terms of efficacy, safety, and stable supply. A drug product is not a single component of the drug substance (the active ingredient of a drug), but a mixture including excipients. Drug product-specific impurities resulting from reactions with excipients and packaging can be present in the drug product. Furthermore, a single drug substance can be used to design drug products with various contents, dosage forms, and formulations. Therefore, when developing a test method for a drug product, sample preparation methods and analytical conditions must be optimized according to the properties of the drug product, and a wide range of test items must be set.

In physico-chemical properties research, we evaluate the functionality of formulations, such as improvement in stability and dissolution by excipients, and investigate the causes of quality issues. The information obtained from the physico-chemical properties research is shared with members responsible for formulation design and used to develop and improve formulations and manufacturing processes, thereby contributing to Astellas’s entire process of creating drug product from the quality aspect.

In addition, I prepare documents for clinical trial application in various countries, transfer test method technology and outsource stability tests to analytical sites inside and outside the company, and conduct basic research for understanding drug product properties and exploring new technologies. -

When do you find your work interesting or difficult?

I find it interesting to come into contact with a wide variety of knowledge and technologies, and to utilize the skills and know-how I have acquired to move forward with my work.

For the development of a single drug product, members with various backgrounds, including synthesis and analysis of drug substances, formulation and process design, work together. Furthermore, a wide range of technologies are used. In order to correctly understand and evaluate the quality of a drug product, not only knowledge of the physico-chemical properties analysis of the drug product and instrumental analysis techniques, but also knowledge in other specialized areas is necessary. Since joining the company, I have been given opportunities to develop various test methods, conduct research on physico-chemical properties, and attend meetings and training sessions with members from other specialized fields. Through these opportunities I feel that my knowledge and skills are expanding every day. I feel a sense of accomplishment when I am able to develop and present optimal analytical methods in accordance with the characteristics of the analyte based on my accumulated knowledge and experience.

In some cases, problems with test methods and analysis, such as a lack of reproducibility or observation of outliers, could occur. It is sometimes difficult to solve the problems because the root cause could not be immediately identified. Even in such situations, I find it interesting to gain new insights through discussions with my seniors, information gathering from other departments, repeated experiments, and trial-and-error. When we reach a solution, I feel a great sense of accomplishment, and at the same time, I feel a sense of growth, which is very rewarding.

In order to work efficiently and effectively, knowledge of pharmaceutical regulations, knowledge of statistics and data science for analysis, and an understanding of the needs of analytical sites for technology transfer and outsourcing are also required. I feel that I have a lot to learn in my research life, and I am motivated every day by the fact that every single task I accomplish with the know-how I have gained is connected to "delivering drugs to patients". -

What is something you would like to challenge yourself in the future at work?

I would like to acquire a wide range of expertise centered on physico-chemical properties analysis, and to be able to lead the project in cooperation with people who are active in other fields.

The work of the Analytical Research Labs. involves various processes from the development stage to post-launch. Currently, I am involved in the project of small molecule solid drug product in the early stages of development. In future, I would like to enhance my expertise in physico-chemical property analysis while gaining experience by challenging myself at various stages and analytical target. Like my seniors, I would like to be able to proactively lead the projects and contribute to the other departments from the viewpoint of physico-chemical property analysis.

In addition to enhancing my expertise, I would like to take on challenges of introducing new technologies and proposing new solutions by expanding my knowledge and skills in other related fields and refining my imagination, creativity, and ability to think critically. I would also like to deepen my understanding of the work in different fields and contribute to promoting effective collaboration that takes advantage of each other's strengths.

Furthermore, I am currently actively involved in joint research with other research institutions and participating in academic conferences, which gives me many opportunities to look outside the company. My dream is to continue to participate not only in internal but also external activities and eventually become a researcher who can contribute to the pharmaceutical industry as a whole through physico-chemical property analysis. -

What attracts you to working at Astellas?

I am attracted to the environment where I can grow and take on challenges.

Astellas has a culture that respects diversity and individual personality, and there are people with various backgrounds, specialties, and careers inside and outside the research laboratories. Moreover, as a global pharmaceutical company, Astellas has many relationships with people from overseas. In e-mails and meetings, we have lively discussions from various perspectives. I feel that I am inspired and broadening my perspective in the global stage. Another attractive aspect is the opportunity for employees to share and enhance each other's knowledge, experience, and strengths through work-related study sessions and debriefing sessions. Furthermore, the company values and respects the opinions of young employees. We are blessed with an environment where young employees are entrusted with important work and encouraged to actively take on new challenges.

In the Analytical Reserach Labs, we have working team (WT) activities to conduct basic research for a deeper understanding of physico-chemical properties and to develop technologies to solve common issues among new drug development projects. I have participated in several WT activities. One of the attractive points of WT activities is that there are opportunities for growth as a researcher, where we can try the development and acquisition of new technologies based on our own ideas without being bound by precedents.

A Day in the work of Hitomi Okada

| 6:30 | Wake up. It takes about 15 minutes to walk from home to the office. |

| 8:00-8:30 | Arrive at work. Check e-mails and the daily schedule. |

| 8:30-9:00 | Analyze the results of the previous day's experiments. |

| 10:00-12:00 | Conduct experiments. In my spare time, check e-mails and prepare documents (most of the documents are prepared in English for the global market). |

| 12:30-13:30 | Have lunch at the company cafeteria. |

| 13:30-14:00 | Discuss experiment details and documentation policies with team members. |

| 14:00-15:00 | Attend meetings with other departments (some meetings are with overseas sites). |

| 15:00-17:00 | Continue experiments and record experiment details in the electronic laboratory notebook. |

| 17:00-18:30 | Prepare reports and meeting materials. |

| 18:30 | Confirm the schedule for the next day. Leave the office (leaving time may vary depending on the day). |

Employee Q&A

I develop analytical methods to evaluate the quality of biopharmaceuticals and conduct research to understand their physical properties.

Graduate School of Pharmaceutical Sciences, Division of Bioinformatics and Chemical Genomics, Master's Degree, Joined the company in 2020

Shintaro Yamane

-

What is your current work?

I am engaged in the development of analytical methods for evaluating the quality of drugs and research to understand their physical properties.

I am mainly engaged in the development of analytical methods and research on physical properties related to the evaluation of biological activity of antibody drugs under development. I am developing analytical methods to evaluate the quality of developed antibodies based on the mechanism of action, such as the binding between antibodies and antigens, and the signal transduction reaction associated with the binding. We use various methods such as ELISA, flow cytometry, and reporter gene assays. We are working on understanding the mechanism of action and examining the test conditions in order to develop analytical methods that can correctly and stably evaluate the activity. The analytical methods we develop are used as part of quality testing to ensure that the manufactured drug product meets the desired quality.

In addition, I conduct research to understand the properties and characteristics of developed antibodies as part of our physical properties research. Analysis of the structure of developed antibodies, stress-induced structural changes, and the correlation between such structural changes and biological activity are analyzed to gain a better understanding of developed antibodies, to select important parameters for quality control, and to provide justifications to pharmaceutical regulatory authorities. The research is carried out in conjunction with structural evaluation information obtained by HPLC and mass spectrometry (MS) at the same laboratory, so a wide range of knowledge is required. I think that elucidating physical properties based on various data is a very interesting part of the research. Of course, collaboration with other laboratories is also indispensable in understanding physical properties. The data on the physical properties of developed products obtained from the manufacturing process research conducted by the Chemical & Biological Technology Research Laboratory and the formulation research conducted by the Pharmaceutical Research & Technology Laboratories is valuable information that cannot be obtained by the Analytical Research Labs. alone. I analyze samples produced in the research process at each laboratory to obtain data on physical properties and provide the analysis results for each laboratory to promote research at each laboratory from the viewpoint of physical properties. -

When do you find your work interesting or challenging?

The process of developing robust analytical methods is very difficult and interesting.

The various analytical methods we develop at our laboratory are used for long-lasting quality testing at manufacturing plants in Japan and overseas. Therefore, they must be robust analytical methods that can evaluate the quality of pharmaceuticals at a certain level regardless of the testing site or the analyst. When developing an analytical method, we investigate factors that may affect robustness, such as the source and lot-to-lot difference of reagents and the manufacturer and model number of analytical equipment, in addition to the operating procedures, analysts, and testing sites, to optimize the testing conditions. In particular, it is very difficult to obtain stable data for cell-based test methods because the analytical results may vary due to changes in cell conditions caused by slight changes in culture conditions or differences in passage number. For this reason, I feel a truly great sense of accomplishment when I understand the characteristics of an analytical method and complete a robust test method after much trial and error.

Another attractive point is that the work of the Analytical Research Labs. is very broad. In addition to the microplate reader and flow cytometer that I am currently using, there are HPLC, GC (and other chromatographic instruments), MS, NMR, DSC, X-ray equipment, and etc. When I was a student, I mainly conducted bioactivity evaluations using cells, but since joining the company, I have also been conducting analytical method development using HPLC, MS and other instruments that I have never used before, so I am learning new fields through work.

In addition to experimental work, we also handle regulatory affairs application and transfer analytical method technology to domestic and overseas testing sites, so I find it very interesting and challenging to work at the Analytical Research Labs., where I am constantly learning new knowledge and technologies. By learning new fields, I am able to gain a deeper understanding of drug development, which always keeps my days fresh and enjoyable. Of course, when learning a new field, I can take on the challenge without worry as my senior experts provide detailed guidance. -

What would you like to challenge yourself in the future at work?

As an analytical specialist, I would like to be able to lead development projects.

As mentioned above, the work of the Analytical Research Labs. requires a wide range of skills, including analytical method development, physical properties research and pharmaceutical applications. Therefore, my daily work is a series of challenges. In the future, I would like to acquire a wide range of know-how in various fields by accumulating these daily experiences, and to be able to lead projects as an expert in analysis. In addition, as a project leader, I would like to contribute to the stable supply of safe and trusted drugs by collaborating with various departments within our company and with manufacturing and testing companies in Japan and overseas. Although I am still a novice in every field, I feel that I am growing step by step as I gradually gain experience in developing various types of test methods, acquiring data on physical properties, and preparing regulatory applications. I would like to continue to take on new challenges and continue to grow.

-

What is the attraction of working at Astellas?

It is the excellent training system and growth support for employees.

We have a mentor system in which you work together with senior employees for the first year and a half after joining our company. They are always available for consultation, so you can work with peace of mind. Of course, other than the mentors, all senior employees are also kind enough to teach you. During discussions, they are always willing to treat each other as equals as researchers.

Astellas is a "treasure house" of experts in various fields, so to speak, and I feel that it is an environment in which it is easy to take on challenges in new fields.

The Analytical Research Labs. is eager to acquire new technologies and research methods, and even young employees are given opportunities to actively take on new challenges. Since my third year with the company, I have joined a new technology development team on a voluntary basis, in addition to my work on development projects, and am working on the establishment of a test method to evaluate immunogenicity which is related to the safety of drugs.

There are also various other opportunities for businessperson to obtain doctoral degrees, study abroad or be posted overseas. The will to grow with the company as well as yourself is respected, and your supervisor actively encourages you to do so.

I feel that Analytical Research Labs. has a particularly good support system. The phrase that left the greatest impression on me during my job search was, "Analytical Research Labs. is a department that values human resources."In fact, few people have the experience in the development of high-precision analytical methods, extensive evaluation of physical properties and pharmaceutical application work that is performed at Analytical Research Labs. during their university days. For this reason, the department as a whole focuses on "nurturing employees," which I feel leads to the enhancement of training programs and growth support.

I am also attracted to the fact that I can grow on a global stage. Astellas has R&D and production sites in Japan and overseas. The projects I am currently in charge of are all global development products, and I sometimes have meetings with overseas representatives in English. In order to obtain regulatory approval in various countries, we file regulatory applications in accordance with country-specific regulations. I feel that the appeal of working at Astellas is that I can broaden my horizons through this kind of work in the global arena.

A Day in the work of Shintaro Yamane

| 7:30 | Wake up. Commute to work takes about 15 minutes by car. |

| 8:30 - 9:00 | Arrive at work. Check email and daily schedule. |

| 9:00-10:00 | Weekly bioactivity evaluation team meeting (members who mainly conduct bioactivity evaluation gather to report on the status of their experiments and discuss what other members are studying). |

| 10:00-12:00 | Experiment (cell passaging, start of cell tests). |

| 12:00-13:00 | Lunch at the cafeteria in the laboratory. On a fine day, I take a walk around the laboratory with my colleagues to refresh myself. |

| 13:00-15:00 | Experiment (measurement with FCM), analysis of experimental results. |

| 15:00-16:00 | Discussion with senior employees about the results of experiments and future studies. |

| 16:00-17:00 | Monthly joint project meeting with other laboratories (sharing the analysis results of research samples from other laboratories and discussing the results and future study policies). |

| 17:00-18:00 | Preparation of progress report materials and reports on experimental details. Occasionally, literature research is also conducted. |

| 18:00-18:30 | Confirm the next day's schedule and leave the office (leaving time may vary depending on the day). |

Engineering Group

Overview

The Engineering Group works on "engineering" and "technology development" activities. In both of these tasks, we work to optimize the entire procedure based on environmental, safety, quality, delivery time, and cost perspectives. We accurately incorporate the requirements of users who are in charge of in-house research divisions and manufacturing plants in the specifications of equipment, and work with external engineering companies and equipment manufacturers to build facilities and equipment. In addition to maintaining close contact with the internal Quality Assurance Division and Procurement, we also maintain close contact with regulatory authorities, and work closely with a large number of related divisions during these construction activities.

Engineering tasks

We construct new buildings, build manufacturing lines, refurbish existing

buildings, and introduce new technologies. In recent years, operational plans that take into account

the entire lifecycle, from the design of facilities and equipment to construction and installation,

testing operations, actual operations, and retirement, have been required. By taking these into

consideration from the design stage, it is feasible to construct more advanced specifications for

facilities and equipment. This is an example of the capabilities of engineers, because how deeply the

entire lifecycle has been considered at the design stage can have a significant impact on subsequent

operations.

Plant construction: We design and construct manufacturing plants. In the past, we built numerous

plants for chemical synthesis of drug substances and oral solid dosages for batch production.

Recently, in addition to these, we have also built manufacturing plants for antibodies and new

modalities for pharmaceutical products. We design and adopt facilities and equipment while meeting new

regulatory requirements.

Construction of manufacturing lines: In order to build new product manufacturing lines and increase

manufacturing capacity, we introduce manufacturing equipment in future spaces at existing facilities

and renovate existing lines. In addition, in the event of aging facilities, we are not simply

replacing equipment, but are introducing equipment with new highly functional technologies. To

introduce these new technologies, we also conduct technology evaluation experiments in collaboration

with various research laboratories.

In plant construction and manufacturing line construction, we pay due attention to the environment. We

work to build facilities and equipment that are energy efficient by introducing highly efficient

equipment and systems so that manufacturing and research activities can be conducted with less energy.

Technical development operations

Quality improvement technologies

Manufacturing equipment technology plays an extremely important role in ensuring

and improving the quality of pharmaceutical products. In order to improve the quality of

pharmaceutical products, the Engineering Group develops and introduces various manufacturing equipment

technologies.

For example, the establishment of a production line for a new pharmaceutical product requires

equipment that will ensure that the quality characteristics for the new product are met; however, such

equipment may not exist in the market and, in such instances, we need to combine existing technologies

or develop new equipment ourselves. Although the quality of pharmaceutical products has been ensured

by taking samples from each process and performing quality tests after the completion of the process,

developing technologies to directly monitor and manage the quality of products during the process is

one example of our developments.

Automated technology

Automated technologies are very important for pharmaceutical products not only to

reduce the cost of manufacturing but also to avoid the risk of contamination by humans. The

Engineering Group collaborates with external device manufacturers in the development and introduction

of technologies for automation of pharmaceutical production lines based on the latest control and

robot/IT technologies.